EXAMPLE

Case: Voith Turbo Safeset

This example is a customer case describing a configurator implemented at Voith Turbo Safeset AB.

The system is developed in RuleDesigner Configurator and supports several different administrative processes for configuring Voith’s products:

- Product selection and configuration of unique product variants

- Automated generation of quotation documents such as 3D models, drawings and product specifications.

- Digitized process for sales and engineering to create quote documents.

- Data collection and generation of unique product manuals.

Values in this solution

- Digitization of tendering processes

- Shortened lead time for quotes

- CAD design automation.

- Increased availability for configuration

- Time freed up for product development

Voith Turbo Safeset builds success with time-saving configurator

Voith Turbo Safeset in Hudiksvall manufactures torque limiters – a kind of safety clutch that is installed inside a drive train and prevents damage to the motor in case of overloads. It is an effective and very valuable solution that is also easy to reset after an unplanned stop.

For Voith’s customers, this often involves very large and expensive drive trains in, for example, tunnel boring machines or large ship engines.

Since each drive train has its own specific characteristics, each torque limiter manufactured in the Hudiksvall factory is customized. This means that drawings and manuals must also be modified or created anew for each project.

Every time a salesperson presents a solution to a potential customer, they need to be able to produce a quote quickly, often based on limited input from the customer.

P-O Berg CEO Voith Turbo Safeset

– This was an area where we had pains. It took a lot of time and we were able to make the dialog between the sales people and the designers faster and more efficient – and with better quality,” says P-O Berg, CEO of Voith Turbo Safeset.

For the design department, this meant a lot of monotonous work that stole time and hindered development. Development and Design Manager Jonas Löfgren explains:

– We made changes to already existing couplings or drawings. We could make a change to the same drawing four times. Monotonous, repetitive work. And there are a lot of quote drawings made every day.

For the design department, this meant a lot of monotonous work that stole time and hindered development. Development and Design Manager Jonas Löfgren explains:

– We made changes to already existing couplings or drawings. We could make a change to the same drawing four times. Monotonous, repetitive work. And there are a lot of quote drawings made every day.

Voith Turbo Safeset asked KonfigDesign to help create a system to streamline the process. The work began with a thorough feasibility study, where all departments involved were involved in developing a concept for a configurator.

– KonfigDesign helped us to examine ourselves. “What do we need?”, “What does the customer need?” and “What is the benefit of this… Is it for my department or for someone else or is it for the customer that we are doing it?”

Jonas Löfgren, Design manager Voith Turbo Safeset

The pre-study is very important and KonfigDesign was very good at helping us understand what we need as a company. And I think that’s the key to us getting a good end product too,” says Jonas Löfgren.

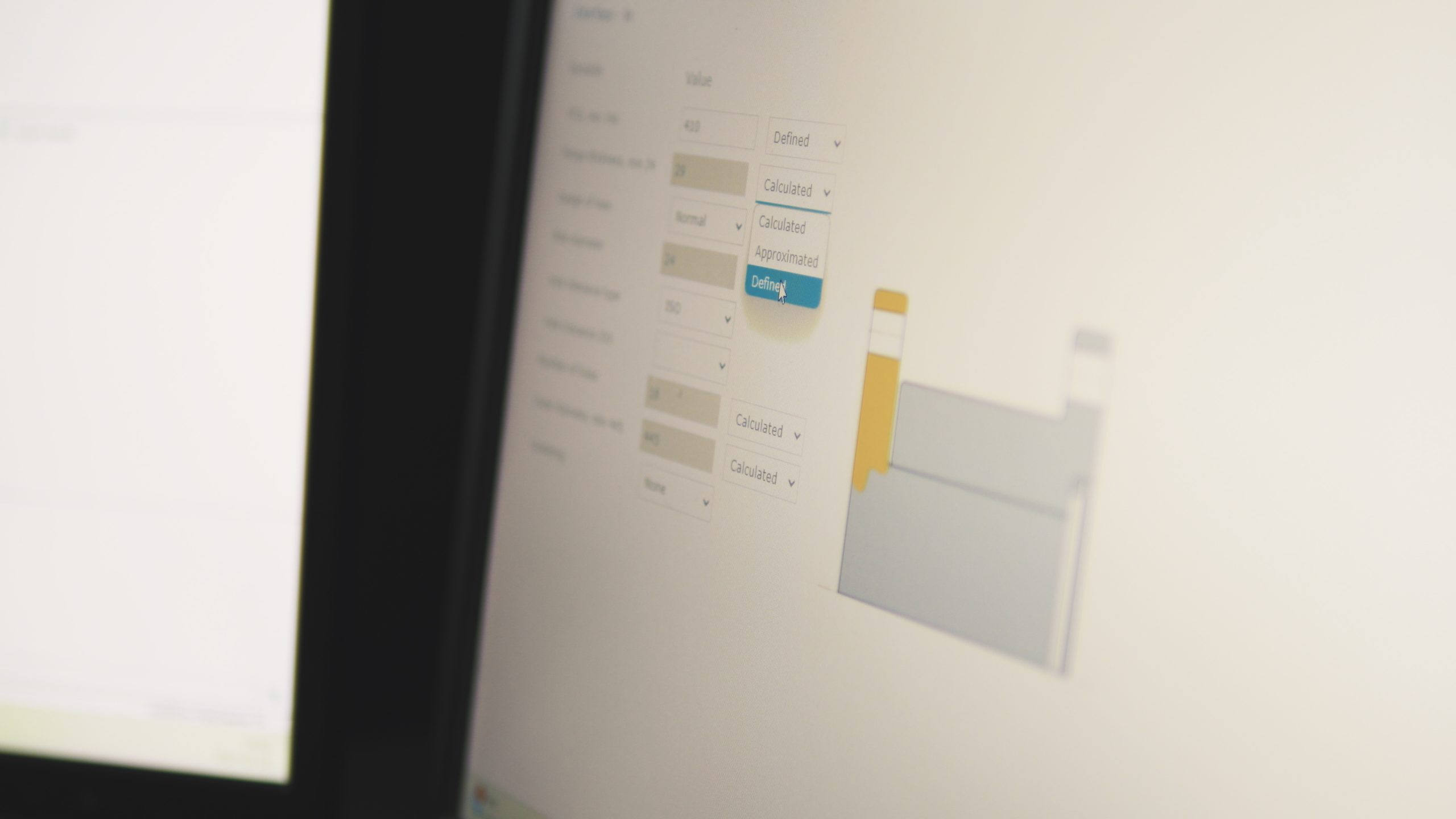

The final product is a configurator built with RuleDesigner Configurator, which is currently used for all quote requests. It enables salespeople to quickly generate quotation documents by showing clear suggestions of products that fit the current request, and the limits for changes to different features.

The configurator also tells you what other issues are currently with the design department, and what the lead time is if you need special solutions that are out of bounds.

– This means that we have a better structure of the tasks performed, where they are in the queue and how much there is to do. Salespeople and designers know where their cases are, what their status is and we get an idea of when they are ready, which means that the dialog and friction between the sales and design departments has improved,” says P-O Berg.

He explains that the whole information flow between customer, salesperson and designer has improved and is much faster because the information is “simply better”.

The sales process has changed from the ground up, says Håkan Westberg, Sales Manager at Voith Turbo Safeset.

Håkan Westberg, Sales manager Voith Turbo Safeset

– Our inside sales people get back from the configurator – basically in seconds – a validation of the design that we can price and send out to the customer. The most important thing is to catch the customer very early when they are interested in our product and be able to give them a solution right away,” he says.

Håkan Westberg believes that the configurator has effectively increased their “hit rate” – the proportion of customer contacts that lead to business, by significantly speeding up the quotation process.

– The quicker we can respond to the customer, the more likely they will be to buy our products.

Another advantage of the configurator is that it enables Voith sales representatives around the world to create quotation drawings on their own, at the customer’s site.

– Which is an extreme advantage. “The customer gets to be involved ‘in design’, and they are more likely to feel that it is their own design, which makes them choose our products,” says Håkan Westberg.

But the collaboration between KonfigDesign and Voith did not start with quotation documents, but with a completely different time thief – the creation of manuals. One effect of working with customized products is that customized manuals are also needed, with specific measurement data and drawings.

Voith had developed its own solution in Excel, but it took about 45 minutes per manual and only a few people could do the job.

– We cut together documents, drawings, diagrams and different parts that became a manual, and in different languages. So it was very much cut and paste. Very monotonous. Absolutely no value creation,” says Jonas Löfgren, Head of Construction.

To streamline the creation of the manuals, KonfigDesign developed a configurator that eliminates much of the manual work. With its help, the manuals are created virtually automatically.

The third and latest version of the “Manual Creator”, as Voith calls it, is based on several different departments helping to input data into the system, which has resulted in a huge time saving for the design department, which is a critical resource in the company.

– With the help of the configurator, we have removed much of the monotonous work. We basically don’t need to spend any time at all. We enter what is needed into a database and then the configurator handles the manual creation completely automatically,” says Jonas Löfgren.

With the help of configuration, Voith can spend less time on, for example, training new designers and salespeople and more time on complex, more value-creating tasks, which in turn leads to faster and better growth.

CEO P-O Berg says that the company has seen an increase in orders over the past three to four years. This is partly due to the improvements that the configurator has brought to internal flows.

– We have been helped by the configurator of course and we can respond faster now. We can get more quotes, we can get more orders and we are growing. It’s a very good symbiosis,” he says.