[Publicerad artikel i tidskriften Cad & Ritnytt nr 1/2013]

A well-defined set of rules automates product development at Voith Turbo Safeset AB in Hudiksvall. It is created with the RuleDesigner tool that helps the designer Jimmy Westberg to scale away unnecessary time, raise the quality level and get an overview of the project’s economy.

Scaling out unnecessary work and reaching higher levels of automation is an ongoing process in industry today. But automation is not just about investing in robots to facilitate production, it is equally important in the entire development chain from idea to finished product.

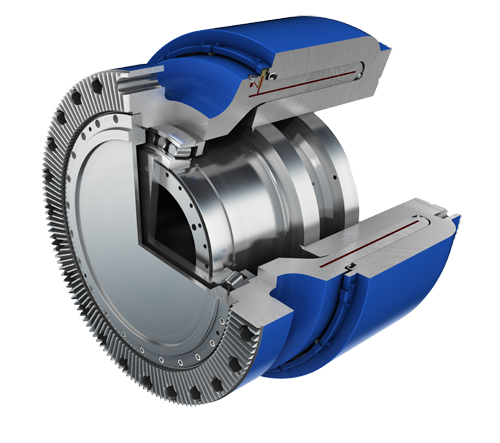

Jimmy Westberg is a designer at Voith Turbo Safeset AB in Hudiksvall. The company develops and manufactures couplings and joints that are designed to release in case of overload, so as not to destroy gearboxes and other mechanical equipment.

These links are entirely customer-specific and should respond to different customer requirements. It is about technical characteristics and the physical space available. The couplings come in different variants with different amounts of detail depending on their complexity. The calculation time in the design work is high.

To scale away as much unnecessary calculation time as possible in the development of these customer-specific connections, Jimmy uses the RuleDesigner program.

– The calculations are infinitely faster with the help of RuleDesigner, says Jimmy. Each calculation is done methodically and based on the definitions we have programmed.

Rules create quality

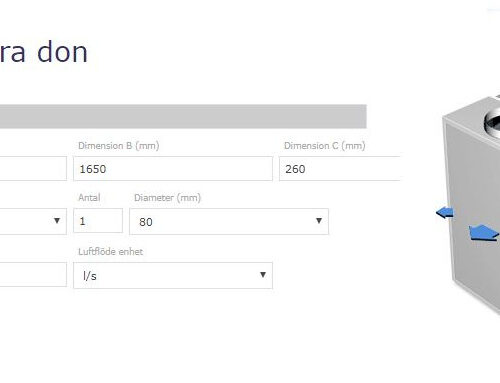

In the program, Jimmy defines a number of conditions, a set of rules that govern the calculations in the CAD system according to the entered properties. The result is a web-based configurator that guides the calculations when developing new connections. This configurator ensures the quality of the calculations based on the setups once defined. Everything is stored in the program. Based on the calculations, an optimal blueprint for production is generated.

He estimates that a configurator manages about a hundred governing rules to a total construction of a connection. The rules govern, among other things, material qualities, friction properties and strength. By first performing an FEM analysis of the structure, Jimmy can use this information to create rules that guarantee a predetermined level of strength. In 2013, work is underway to modify the configurator in order to run it in live mode later in the year.

Jimmy is currently working on a project to rationalize the management of new information that arises in the development of these specific links. It’s about stripping out unnecessary data in designs that you don’t need. Alignment work guided by the program.

– We program RuleDesigner so that the program sorts out details from the designs to find the optimal solution. We would otherwise have had to calculate this by hand.

The idea is that the processing of new data will be done automatically using the program. For Jimmy, this is about creating rules that control the CAD system and perform the desired modification of the design data. This is then applied for each new piece of information that needs to be adapted.

– Once we have established the quality of the calculations, we should not have to redo them again and again, the program will take care of that for us.

Keeping track of project finances

But RuleDesigner doesn’t just help streamline the design process for Jimmy and his team. It is also a tool to keep track of the finances of the project. In the creative phase, costs are not always directly in view.

– The cost is secondary because you are primarily solving the customer’s problem. It is not self-evident to also consider the price of details or the cost of programming a complex design.

In the regulatory framework that is being built up, it is not only the characteristics of details that are taken into account, but also purchase prices. The program helps to control project costs. In practice, this is done with specific control numbers.

– A higher priced component scores high and a cheaper component scores lower. The lower the score, the more economically advantageous the component will be.

This system can be easily adapted to the customer’s budget. Similar quota systems can be applied in other areas, such as time. The program will therefore not only be a tool to streamline the actual design work. By also introducing other production-critical factors such as economy and time, the program takes on a broader function. The development chain from idea to finished product becomes transparent.

– We save days by working this way,” says Jimmy. By standardizing the development phase of the couplings, we save design hours, review hours, preparation hours and programming hours in machine. This gives us control over costs and a higher quality of the project.

Love Janson, Comwise