The development of a customized ventilation device has several steps, from calculation to manufacturing. Repus Ventilation AB is now working on introducing an automated process that will save the company time. The idea is to make it more efficient to produce drawings, quotes and production documentation using a configurator. This benefits the company, which is in the middle of an expansionary phase.

The construction industry is booming. The favorable economic situation increases Repus Ventilation AB’s opportunities to grow. The company develops, manufactures and sells ventilation solutions. In order to take advantage of the situation and expand, they want to streamline their operations.

We are developing new ways of working that will automate our processes, says Mattias Kranz, CEO. It frees up time for us.

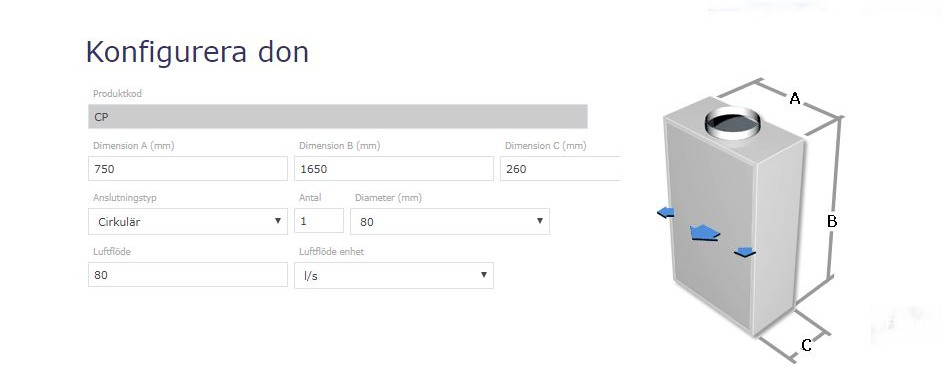

A standard supply air diffuser can be difficult to position if the space is tight. Therefore, a customized actuator is required whose dimensions are calculated taking into account different requirements. It is carried out by a ventilation consultant who can make the calculations in the web-based tool that Repus Ventilation has on its website. The results of the calculations are then used in different areas.

Mattias is now planning to streamline this workflow. By connecting the RuleDesigner configurator, many tasks will be automated. The company is in a transition phase where old routines are to be replaced with new ones, and KonfigDesign is a supportive partner in this process. Mattias explains how it is supposed to work.

– With the help of a plug-in, calculation data should be automatically downloaded to the CAD systems used by the consultant. A 3D drawing is automatically generated. Together with technical data, the information will be passed on to the construction project and inserted into their drawings and BOM lists

Configurator at every step

A flow occurs and flows from calculation to projected don in the automated process. Repus Ventilation is then contacted by a ventilation contractor to obtain a price for the designed units. This too is automated with the configurator.

– In the next step, our CRM system will be connected to the configurator which will retrieve customer details, prices and other data and generate a quote to be sent to the contractor.

When the actuator is finally manufactured, the configurator converts the drawing data into production data. There’s no need for manual intervention, it’s automatic in the digitized process.

Digitization saves time

Once the new way of working is in place, Mattias or his colleagues do not need to be involved in every step. This is done by the configurator, which collects data and sends it to the right user in a digitized flow. From the calculations carried out by the consultant to drawings, quotes and production documents.

– We can already see how much time we will save,” says Mattias. This leaves more time to support consultants as much of the administrative work of managing tenders has been scaled back.

Every day, the automated process will bring benefits to the company.

– What takes hours today, we can do tomorrow at the touch of a button.

Love Janson