Many manufacturing companies spend a lot of time creating item preparations in their ERP system. Now KonfigDesign offers an automated solution for this. First up is an integration with the Monitor business system.

In the case of new product variants or when a contract manufacturing company receives requests based on the customer’s CAD models and drawings, a lot of manual work is often needed to build up a part structure, a so-called preparation in the ERP system. A preparation is needed, for example, to be able to create an occupancy in the workshop and the need for purchased materials, which in turn can provide an answer to the expected delivery time. In the event of an order, the preparation forms the basis for work order documents, reporting and post-calculation.

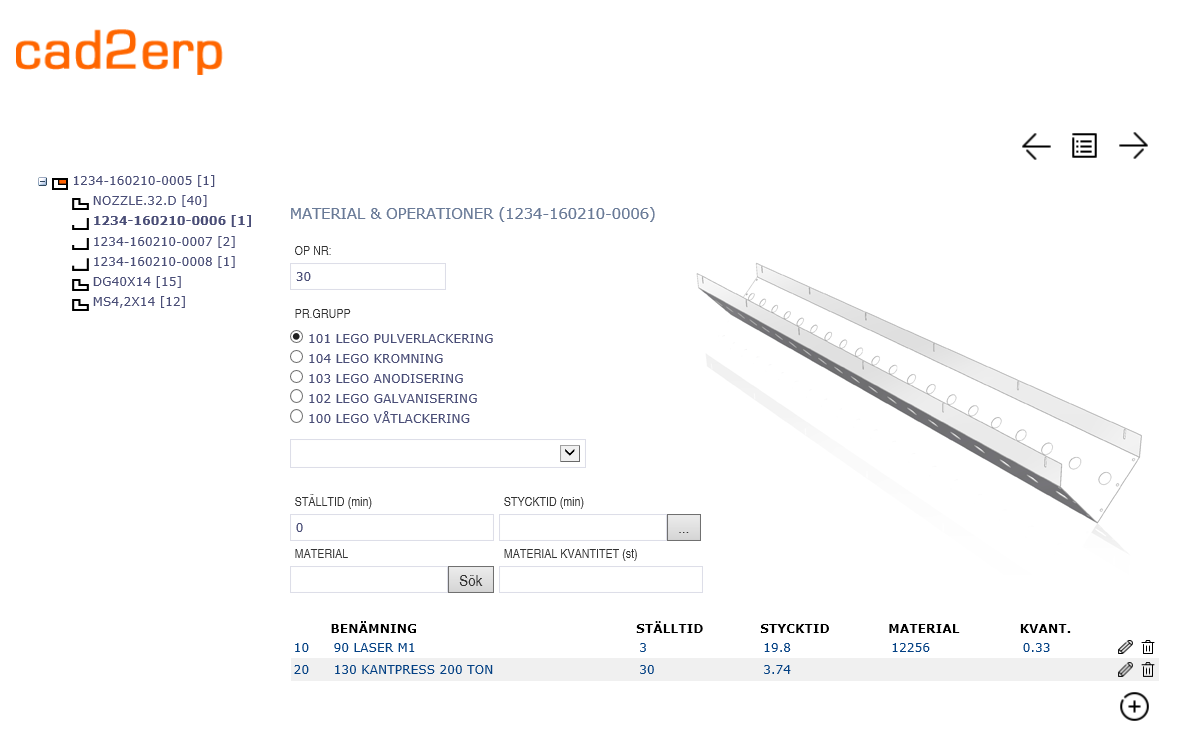

Using RuleDesigner software, KonfigDesign has created the CAD2ERP solution, which integrates with the leading CAD systems on the market and reads the structure of the article directly from the CAD model. Using a web-based guide, the article can then be supplemented with additional information such as machine operations, setting and cutting times, material consumption. Finally, the item is entered as a preparation in the ERP system. Drawing bases are created automatically and can be linked to the part preparation. Even complex articles can be prepared in this way in a very short time.

With the help of CAD2ERP, many valuable effects are achieved:

- Time freed up from drafting work

- Shortening response times for requests for quotes

- Input errors in the ERP system are minimized