Movomech manufactures lifting devices for customers around the world. By automating the flow from the salespeople with a configurator, the customer immediately receives a proposal for the rail system, a 3D model and a price. We cut unnecessary steps and sales work is improved,” says project manager Göran Nilsson.

Keeping track of flows is becoming increasingly important. Especially when you operate in a global market with both your own sales organization and dealers spread across the world. This is the case with Movomech, which supplies lifting equipment to industrial companies in several sectors.

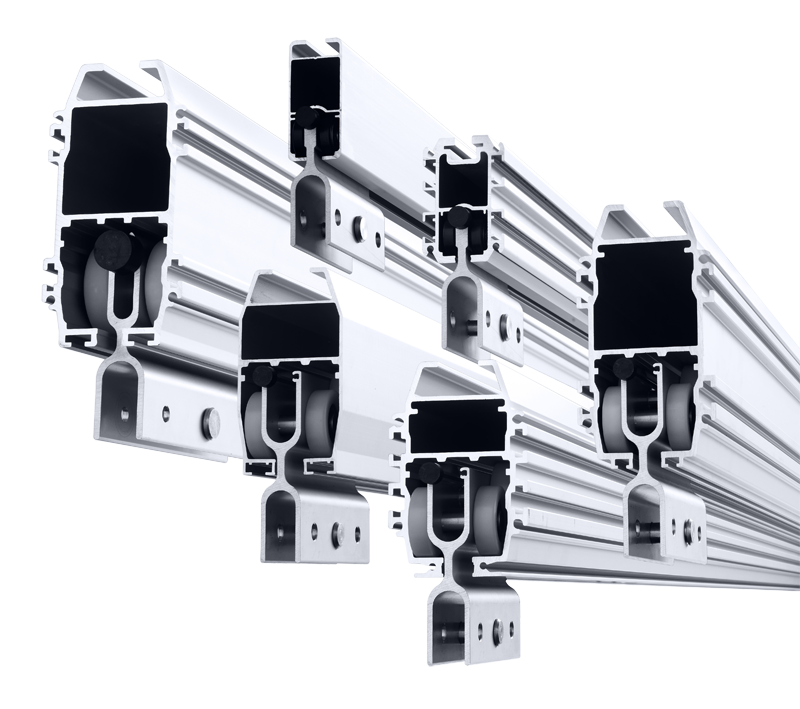

– We supply rails, trolleys and lifting equipment in a customized rail system that meets the need that you have, says project manager Göran Nilsson. We can also help with individual components if the customer wants to complete their own device.

A customized rail system has a multitude of characteristics to be defined, ranging from different types of rails and profiles, suspensions and to lifters. Several choices have to be made to produce a device that meets the customer’s requirements. However, the program used to specify this was no longer up to scratch.

– It was an older text-based system that was difficult to update and did not keep up with our developments. We wanted to distribute the information in several ways and we realized that it had to be replaced with a more efficient solution.

But the need was greater than that. The company also wanted to create a better way of communicating with both its own sellers and several retailers around the world. The chain of information was long and not productive. Enquiries were sent to the sellers who in turn contacted the designers who produced a proposal for the rail system. The proposal was then sent back to be presented to the client. The workflow also depended on everyone being available, having time and having the right data at all stages.

Tailor-made configurator

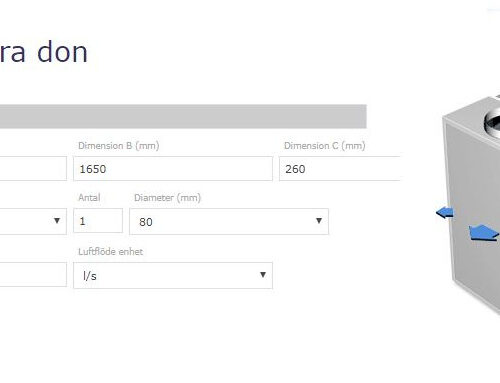

The need to automate the way we work grew. A collaboration was initiated with KonfigDesign in Hudiksvall, who customized a configurator in the RuleDesigner program. It specifies the characteristics of the device in choices that are made in a defined order. You also decide what strength to apply.

– Entering the rail system load produces values that the configurator uses to select the profiles that allow the load and discards those that do not.

Once the selections are made, the configurator has put together a working rail system with parts list. All information is stored in a database.

– The system has a safety feature as you cannot skip any step in the selection. Then the regulations sound the alarm.

The technical documentation is provided to the customer in 3D. While determining the characteristics of the rail system, the same information is generated in a CAD file by the configurator. The customer can place this 3D model in their digital factory layout and conclude if it fits. Designer Emil Månsson has worked on integrating the configurator with Movomech’s CAD system. The information flows from the CAD system to the customer via the configurator.

– A feature of RuleDesigner is that the configurator retrieves data from Inventor’s library automatically and creates documents directly.

The company wants to be self-driven and able to work in a flexible way.

– We have built this system so that we can customize the configurator ourselves if we want to update values or add new profiles. The information should be conveyed in a simple way to the sellers.

The web supports sellers

Sellers can access the configurator in a web browser.

– The programming of the HTML code is done automatically without our intervention. However, we have decided what the interface should look like to work on computers, smartphones and tablets. Everything is hosted on our server and is available as long as you have an Internet connection.

On the Movomech website, the configurator is available under the EConfig tab on the menu where the user logs in.

– We want to make this site as simple and educational as possible,” says Karin Domeij, who has worked on the graphic communication. We have chosen to have large icons with illustrations rather than having to scroll the page.

The configurator is also integrated with the ERP system.

– “The customer receives a proposal for a rail system and at the same time gets a price from the business system, a price that is correct and linked to the discount they have,” says Göran Nilsson. In addition, the quotes are standardized using the configurator and are provided with our logo.

When the salesperson visits a customer, a proposal for a lifting device with specifications and dimensions, parts list, 3D model and an accurate price can be provided directly at the factory. Everything is available via the web once the properties are entered and presented directly. There is no need to call or email anyone, nor to take time differences into account. A retailer receives a document which he can modify, add his logo and add his final price to the offer.

When the customer accepts the quote, the data from the configurator goes to the warehouse where the components are picked and delivered.

Simpler flow saves time

The flow of information is automated. The salesperson no longer needs to contact departments, but can make a proposal for the hoist himself in a conversation with the customer and get the right price. The quotation is provided with 3D data and the customer can immediately see if the dimensions of the rail system are correct. A new way of working is emerging in the company. This saves time, says Göran.

– We have cut several hours and reduced the time per order by around 85%. The number of sources of error is minimized because fewer people are handling the information. It ensures our delivery quality, shortens the sales process and makes flows easier and safer.

Love Janson